August, 30, 2021 by Andrew Farmer in BJD and Smart Doll Printing

One thing about the Smart Doll that originally drew me to it as a product was its frame. The frame sits underneath the vinyl body and is the heart of articulation for the doll. All vinyl shell pieces are heated up with a heat gun or hairdryer and wrapped around the frame. Some of the areas like the upper legs are a very tight fit and almost stick to the frame.

Many years ago, you could buy the frame disassembled, which was really cool if you were into building gunpla or the likes.

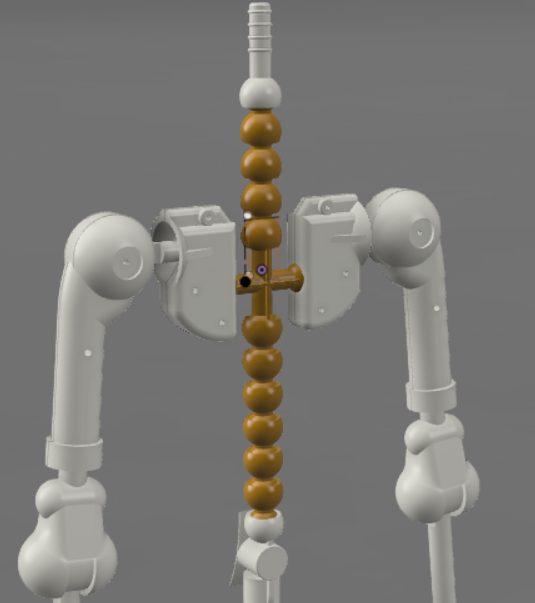

Using my own Smart Doll as reference, as well as images from the internet and Smart Doll website, I set to work learning more about CAD programs like Fusion360 and creating my own replica of the frame. The first thing of note was the spine of the frame, which replicated almost a human like spine with 9-11 ball-joints with a decent amount of flexibility to them (30 degrees each).

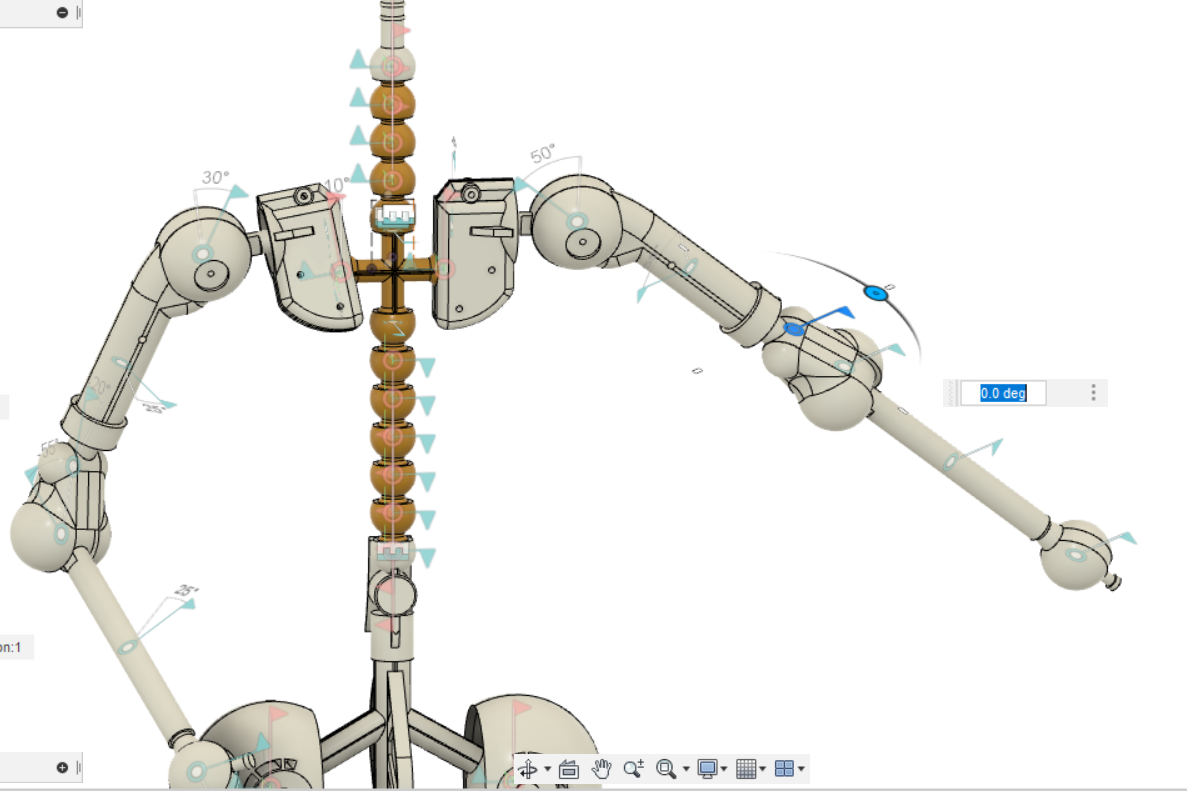

Next was the shoulders, upper arms, elbows, lower arms and wrists. All of these combined gave the frame an incredible amount of articulation. Shoulders and upper arms allowed for 360 degree Y/Z axis movement, and 200 degree X/Z movement. The double jointed elbows allowed for a greater range of arm movement, including the ability to rotate 360 degrees on the X axis using the joints between the upper arm and elbow.

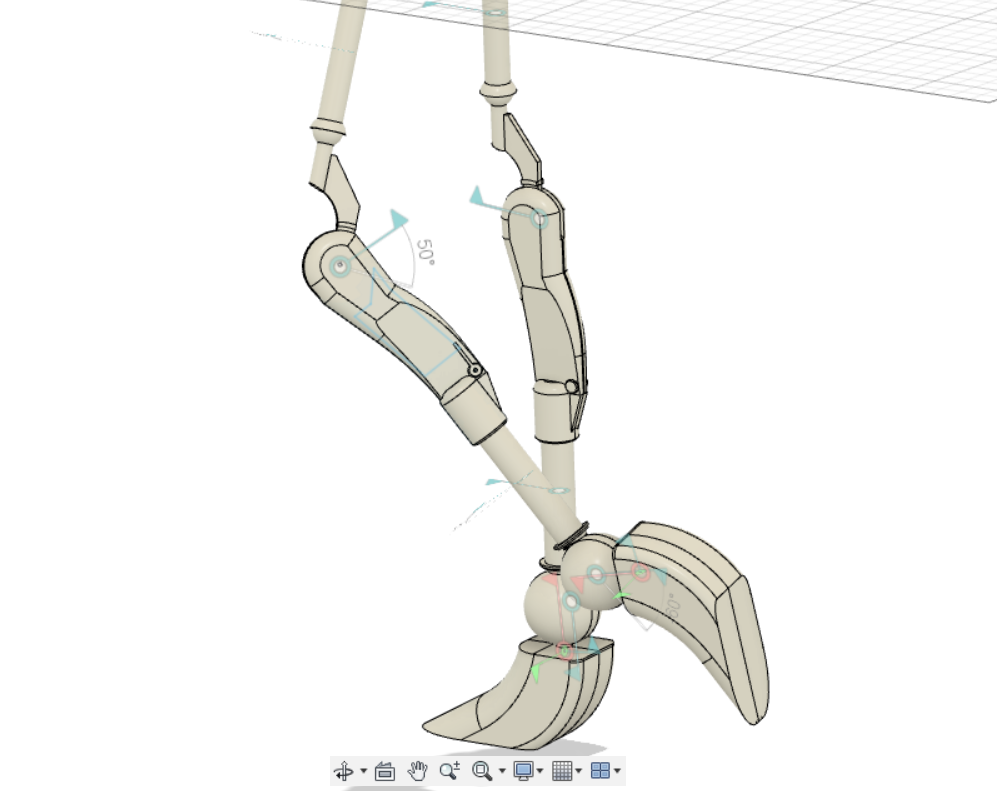

Example of the flexibility of the arms and shoulders presented in Fusion360

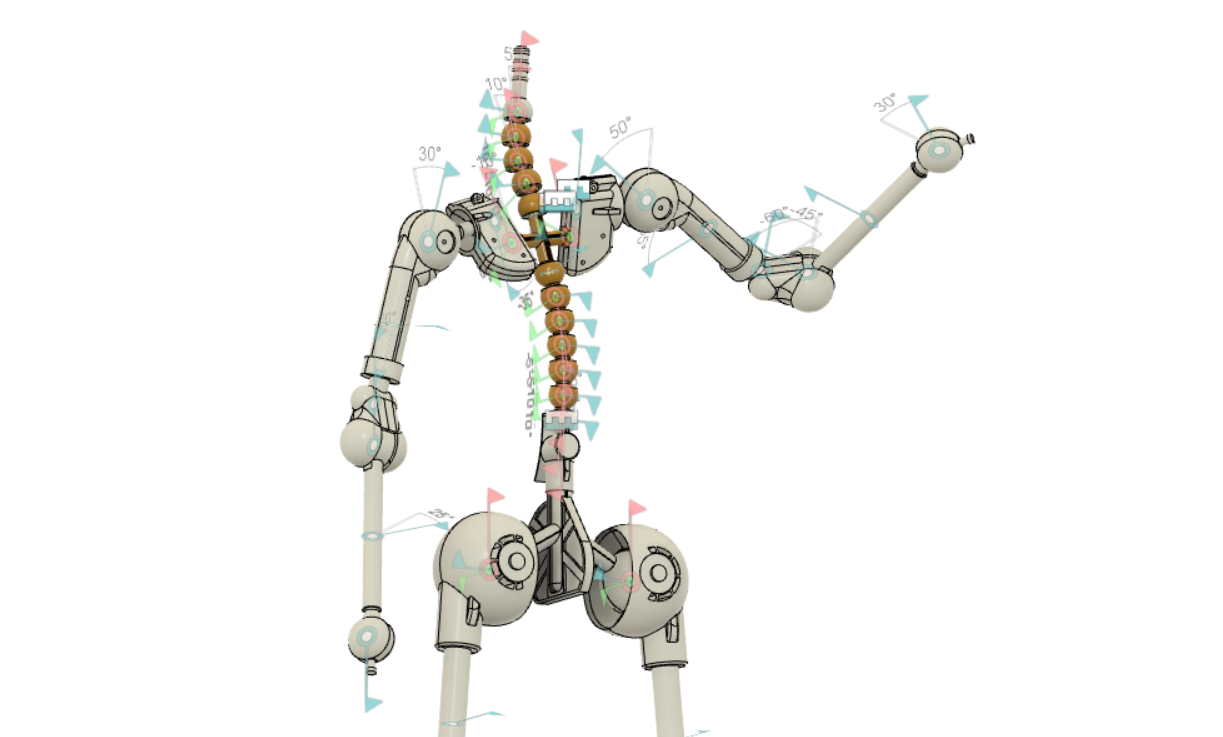

Another example, this time showcasing some articulation in the spine as well.

Up next was the pelvis, hips and upper legs. The hips had a decent amount of flexibility in them, being able to rotate 50 degrees along the X axis, and 360 degrees on the Y/Z axis. Clearly this was not needed, and at max 180 degrees would be needed there.

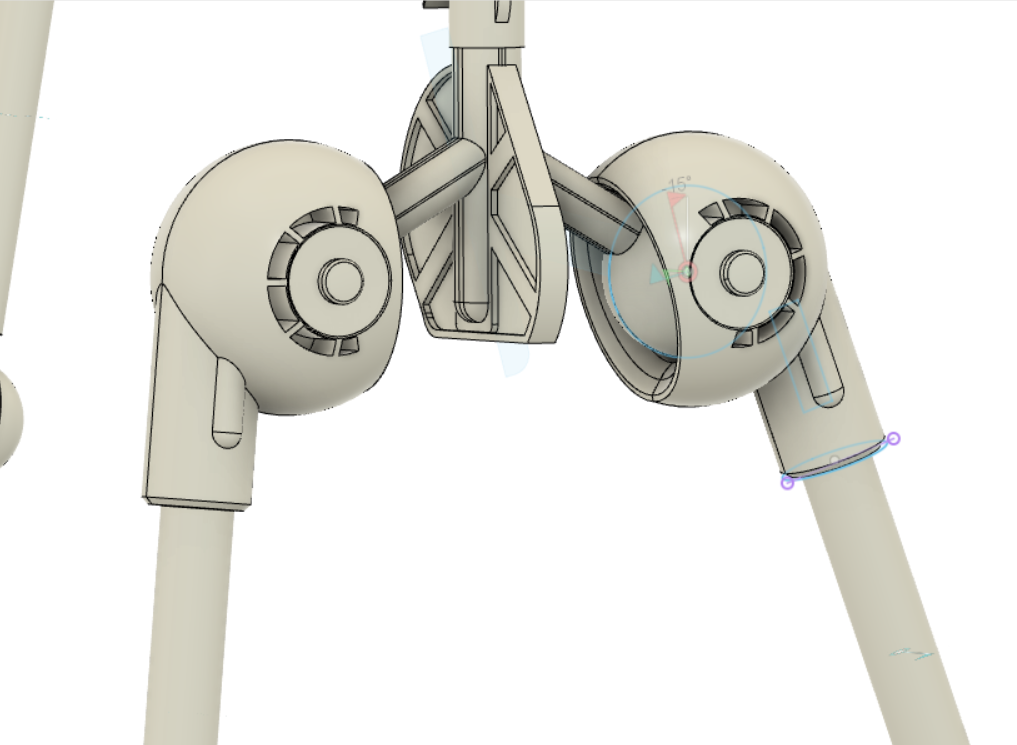

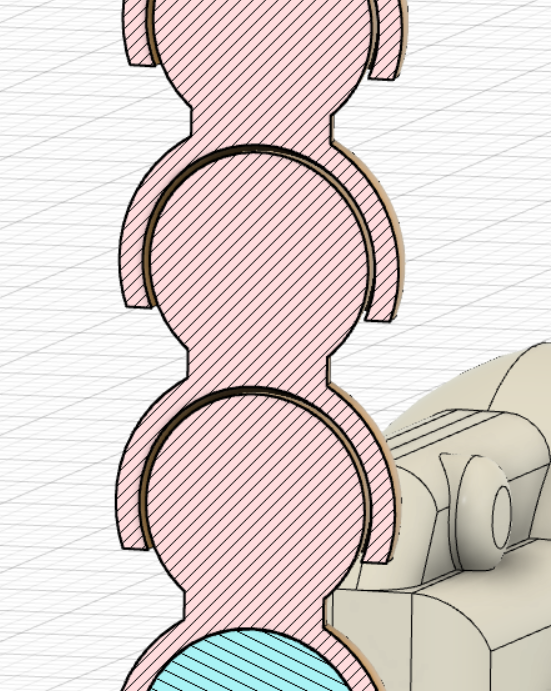

The Hips and Pelvis are made of multiple parts in order to print on a SLA printer easier

Finally, and most importantly, was the legs. The legs proved a little challenge in that I was running out of space. The scale of the replica was growing and I had to be careful with my measurements. I couldn’t make the legs too tall, otherwise the top half would look very silly. This proved a problem with the lower legs, which I had to make shorter than I would have liked to. The legs have a large amount of flexibility. The upper leg-to-knee join is able to rotate 360 degrees on the X/Y axis, the knee is able to bend 110 degrees backwards and the foot is able to rotate 360 degrees on the X/Y axis as well as move back and forth on the Y/Z axis.

An example of the legs articulation

By far the most challenging part of creating a replica was printing the parts and connecting them together. Despite doing my best to measure accurately, the material I was using (fragile UV resin) proved very stubborn when connecting together, often either slightly too big and shattered upon joining, or too small and loose, proving no connect ability. This showed the weakness of ordinary UV resin, which really should not be used for interconnected moving parts. I must have wasted at least 1 litre of the stuff reprinting parts only for them to break again. I had to make several minor measurement adjustments over a month and a half to get it just correct, only for it to break from myself making a careless mistake. In the future, it would be wise to print with a flexible PLA, ABS or resin. These materials can be costly however. Flexible resin in Japan is difficult to get, and can cost at least 8000円 for 500ml.

A graveyard of broken, mismeasured pieces.

As assembly continued, I had to use sandpaper and files to make slight adjustments to the printed pieces, being careful not to over- sand and make joints too loose. It’s important to wear a mask when working with sandpaper and resin as it creates a fine dust which can be bad for your respiratory system.

And the final result…

Well, after a colossal amount of trial and error, we have a functioning, moving frame. However, the spine is unable to handle the weight of the arms, and it cannot stand up freely due to how the feet were designed. While all parts move and remain attached, some are very loose, while others are very tight!

CHECK OUT THE VIEWABLE 3D MODEL OF THE FRAME HERE

Ultimately I concluded that this was due to several factors

In the future I will revisit this frame and redesign some parts to make it more compact and sleeker. I will aim to use flexible ABS/PLA and an FDM printer next time.

It was a very good learning experience which took far longer than I expected, overall totalling 3 months of on and off work.

Thanks for joining me on this journey!

March, 24, 2021 by Andrew Farmer in Japan

Jordan Peterson

When you are airborne, what can you do? With no ground beneath you and no objects to grab a hold of, what is it that you can do? It certainly does seem helpless, at the mercy of all that is more powerful that yourself.

Inertia and Gravity. According to the Oxford Dictionary, Inertia is the state of which something continues in its existing state of motion in a straight line, unless an external force changes said state. Gravity, the force of which attracts mass to the centre of the earth, or to another body. If Gravity is pulling you on its own whims, you had better hope that any inertia you created before becomign airborne will carry you to a safe resting place.

Putting faith in Inertia as you take a leap, and putting hope into yourself that the inertia you created, is enough to see you through to the other side.

In 2007, in the midst of my first senior year of high school, I stumbled across a video of a Stormtrooper dancing in Tokyo on YouTube. Being a massive Star Wars fan at the time, this was the coolest thing in the world to me. Star Wars and Tokyo? What more could you want!

Upon researching the man behind the video, I found out his name was Danny Choo, an IT engineer originally from Britain; living in Tokyo. He had his own blog featuring high quality photos of places all around Japan. Since then, I became a regular visitor to his blog, keen to learn more about all the adventures you could have in Japan. Danny often included reviews and photos of the latest figures or new products being released by Good Smile Company. It always made for a good read to read about his adventures in the anime industry.

Way Back Machine capture of dannychoo.com in January 2008. Very nostalgic!

I have had the pleasure of following Danny Choo on his blog through the years. He became an inspiration to me. An everyday man who, going through the big rollercoaster of life, despite tremendous setbacks, followed his desires and dreams. He is always looking out to improve himself, the life and the people around him, not for money, but for the sake of his passion. This really resonated with me.

Despite becoming busier in his life, Danny would always find the time to post something inspirational and inspiring on his blog, or his various social media accounts which I would then use to reflect on my own life.

Some of my favourites include his Design Philosophy and How Discovering Japan Changed My Life. Both posts contain some great life stories and thought provoking ideas that really make you reflect on what gives a life meaning.

Mr. Choo and I, two years apart.

As I grew older, I found myself reflecting on what I wanted to achieve in my life, working as an IT Engineer and a supervisor at an Australian chain supermarket, while fun and challenging, really wasn’t inspiring nor fulfilling. Day-in, Day-out routine on the computer was draining. I felt more at home interacting with people, and I loved to draw, code and create.

I came accustomed to the comfort of everyday life. I grew up and lived my entire life in the north eastern countryside of Victoria, Australia. My family, friends and loved ones were there and I had income and a roof over my head. It was safe and secure. After all, the ship in port is the safer one.

…but it also felt like as if the sky was a dome, looming over, never allowing escape. I became petrified of the unknown, what ifs made me feel incredible uncomfortable to the point where I would panic.

The region where I grew up

While I had visited Japan multiple times throughout the decade and made many companions there, I felt that it was beyond me that I could pack up and move across the world. Thinking about it felt absolutely impossible. It wasn’t until the middle of 2016 that I started seriously considering it, after watching the final LoveLive! live concert at a local theatre in Melbourne City. It inspired and filled me with energy to really try a new beginning.

…however the fear of the unknown still was too strong.

Life marched on, without any dramatic changes, people came and went, seasons passed, but I remained the same.

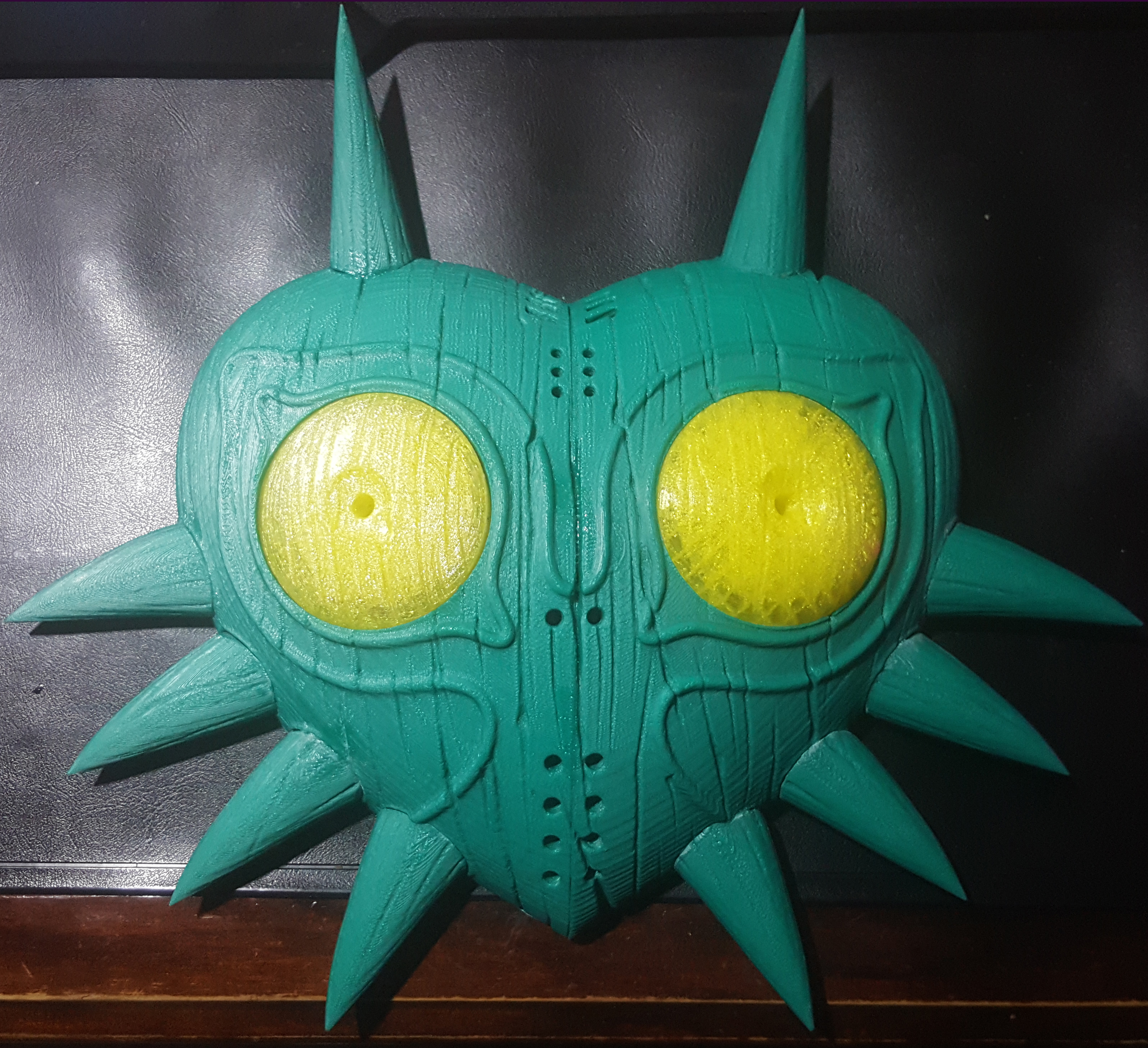

In 2016 after returning from a trip from Japan, I took up 3D printing on a whim and instantly fell in love with it. Being able to make physical objects of essentially anything you could think of in your garage was the coolest thing in the world. For the next two years I played around with 3D Printing, modifying printers, upgrading them, constructing small Arduino projects, printing 1:1 scale cosplay props and even began constructing fully 3D printed 1:1 scale human robot. All the while the weight on my mind that nothing will ever change, things will remain the same, you will die without ever achieving satisfactory, grew heavier.

Majoras mask from The Legend of Zelda printed with ABS and seethrough PLA. 1:1 scale. Designed to have glowing eyes.

a 1:1 scale T-45 Helmet from the Fallout series. Printed with some Z Axis Banding unfortunately. Pipes from a local pool shop. Flashlight omits light.

An ongoing project before moving to Japan. The inMoov robot is designed to be fully 3d printable.

After a small visit to Japan in early 2018, I stopped by the Mirai Store in Gotanda to pick myself up a Chitose Smart Doll and hopefully say hello to Mr Choo again. I had a brief talk to him about my hopes that maybe one day, I hope to find the courage and will to move to Japan, but at the moment it was difficult.

What Mr. Choo said next hit very hard

And he was right…

Soon after I returned home, I began researching in earnest; methods to live and work in Japan. I had heard of the “Assistant Language Teacher” role before, however, I also read a lot about the negative reputation it had. If I was going to do a job, I wanted to take pride in it. After all, you should always strive to do your best at your passions. Learning is something you constantly do your entire life, and I wanted to do a good job of it. After some more research, I settled and applied for the English conversational school AEON, whom of which had the best reputation among these companies in the industry.

The ever popular Akihabara Electric Town, shortly after my move to Japan, looking south down the main road.

In November 2018, I made the official move to start working in Japan, but not without a long term goal of living a dream working at the Mirai Store. During my limited downtime when not working, I have been studying various 3D printing techniques, modelling programs (Maya, zBrush) as well as constructing my own CMS from scratch to display my work.

Since moving to Japan, every day has been exciting, even mundane things like paying taxes. It’s because it’s different from the norm. It’s an adventure. Meeting new people, exchanging cultures and language, trying new activities and finding new hobbies. Adventures aren’t always sunshine and rainbows, but that’s what makes it what it is.

The Tokyo Area at the beginning of the 2020 COVID-19 lockdown

Sometimes I wonder what life would have been like, had I stuck to a more conventional path. Sure, I might be more well off money wise, I might be more comfortable, but would life be an adventure? Would it be exciting? Would I enjoy what I was doing? Every day I wake up, I learn something new about the world around me. I have made unique friends I never would have made had I stayed in the dome of comfort back in Australia. In all honesty, I had no idea I would even get this far!

I stopped by the Mirai Store briefly in May 2019 to make some purchases and hopefully have a quick chat with Danny. I made mention of my self-study and he handed me his business card, informing me that while he can’t guarantee anything, to send him a message when I felt ready. Never in my wildest dreams did I imagine that an opportunity would present itself.

Now, finally after all this time, I feel ready to make that great leap and let the Inertia do the rest.

In the words of Danny -